FLOW METER

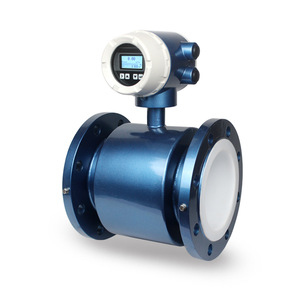

Electromagnetic Flow Meter

Full bore flow meter is a cost effective Electromagnetic Flow meter for conductive liquids such as Raw Water, Chilled water, effluents, Potable water and industrial chemicals. Using time proven electromagnetic flow metering principle. Since there are no moving parts, the Electromagnetic Flow meter gives years of maintenance free service. Its performance is independent of temperature, pressure, density and viscosity of medium. The flow meter is obstruction less and hence the pressure drop is almost negligible.

| TECHNICAL SPECIFICATIONS | |

| Size: | DN 15-1000mm |

| Accuracy | 0.5% of the full scale value |

| Lining Material | PTFE, Hard Rubber, and Polyurethane |

| Electrode Material | SS316, Hastealloy C, titanium |

| Temperature Range | 10 Deg to 120 deg C |

| Ambient Temperature | 10 deg C to 60 deg C |

| Display Type | Integral or Remote (as per the requirement) |

| Protection Class | IP65, IP68 (Optional) |

| Output Signals | 4-20 mA, RS485, Pulse |

Vortex Flow Meter

Vortex flow meters operate under the vortex shedding principle, where an oscillating vortex occur when a fluid such as water flow past a bluff body. On the downside, they have certain unavoidable limits, like pressure drop and installation needs. On the upside, you get flexibility, accuracy, and advantages like steam quality measurement

TECHNICAL SPECIFICATIONS | |

Size | 15 mm to 300 mm |

Body style | Flanged type |

Applicable Fluid | Liquids, Gases and steam |

Operating Temp | -30 deg C to 300 deg C |

Accuracy | ± 1% |

MOC | SS316 |

Mounting | Integral/Remote |

Converter MOC | Aluminum Alloy |

Signal Output | 4-20 mA and RS 485 |

Open Channel Flow meter

Open channel flow meters measure the flow of liquids that are open to the atmosphere at some point in the measurement system.The transmitter has the formulas for 20 commonly used flumes and weirs which allows for a fast set-up. In case of custom built weirs with unknown level and flow relation, a 32 bit linearization function allows for accurate measurement. The instrument offers 2 Flow totalizers for volumetric flow measurement. One of the totalizers is resettable while the other is not.TECHNICAL SPECIFICATIONS OF OPEN CHANNEL FLOW METER | |

Range | 0-12 meters depth |

Weir | Required as per design |

Accuracy | ±2% of FS

|

Mounting | Wall mounted

|

Protection class | IP65/IP68 |

Sensor Cable | 15 meters can extend up to 30 meters |

Power Input | 100- 240V AC |

Output | 4-20 mA |

Data Logging | Optional |

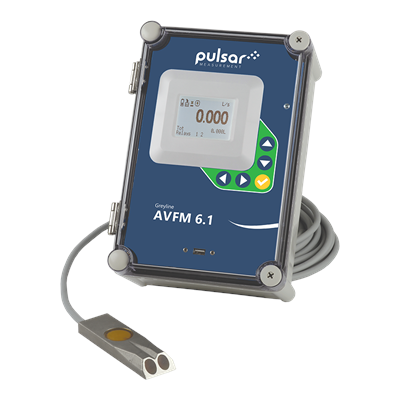

Area Velocity Flow meter

AVFM measures both Level and Velocity to calculate

Flow in an Open Channel or Partially filled pipes.

Flow velocity and water level can be measured simultaneously by one sensor! It can be used only by fixing the sensor to the bottom of a water channel. Large-scale constructions such as weir and pipe establishment are not needed.

- Flow velocity and water level are consecutively measured by one sensor.

- No weir or flume is needed.

- It is easy to set the sensor using a fixing screw and mounting bracket.

- All necessary settings are to enter the pipe diameter and water channel width. There is no difficult setting.

Even a high-speed flow of up to 6 m/sec can be measured.

TECHNICAL SPECIFICATIONS OF AVFM | |

Electronics Enclosure | Watertight and dust tight NEMA4X (IP66) |

Accuracy: Level | ±0.25% of Range |

Velocity | ±2% of Reading |

Power Input | -240 VAC, 50-60 Hz, 5.28 Watts (Standard Feature) |

Outputs | 3 isolated 4-20 mA Outputs |

Operating Temperature | : -20 Degree to 60 degree |

Sensor Type | Available in fixed as well as potable instrument |

Channel Types | Round Pipe, Rectangular, Trapezoid Shapes |

Turbine Flow Meter

The SS Turbine Flow Meter is widely demanded in the market due to the unmatched quality and unsurpassable performance. The flowing media engages a vaned rotor causing it to rotate at an angular velocity proportional to flow rate. The pick-up coil senses the spinning motion of the rotor inside the pipe converted to mA signal by electronic circuitry. Additionally, customers are eased with the availability of the Gas Turbine Flow meter confirming to international standards.Features- Simple & cost effective construction.

- Provides wide flow ranges.

- Outstanding accuracy for clean & low viscosity applications.

- Operates over wide ranges of temperature & pressure.

- Additive features of remote control unit for programming.

TECHNICAL SPECIFICATIONS OF TURBINE METER | |

media | Oil, Water, Distilled Water, DM Water |

Line Size | 0.5”to 10″ |

Temperature | 20C~120C |

Output | 4~20mA DC and Pulse(Standard) |

Power Supply | AC 85~230V, 50/60Hz or DC 24V or Battery (3 year) |

Operating Temperature | -20 ~ 120 Deg C |

Ambient Temperature | -20 ~ 50 Deg C |

Accuracy | 1.0 %, 0.5% |

Output Signal | 4~20mA DC and Pulse (Standard) |

Display | L C D 2 Line x12 character (Rate Flow /Total Flow) |

Service | Clear Liquid, Gases, Air, solvent. |

Enclosure | IP67,IP65 |

MOC | Body – SS 316 /Teflon /PP, Flange -SS 316 / Teflon / PP, Rotor – SS 410 (Optionally Teflon coated) |

Process Connections | Flanged, Threaded |

Enclosure | Flame-proof, IP-65, Gr.I,IIA, IIB, CMRI Certified |

Mounting | In-Line, Horizontal |

ONLINE MONITORING SYSTEM

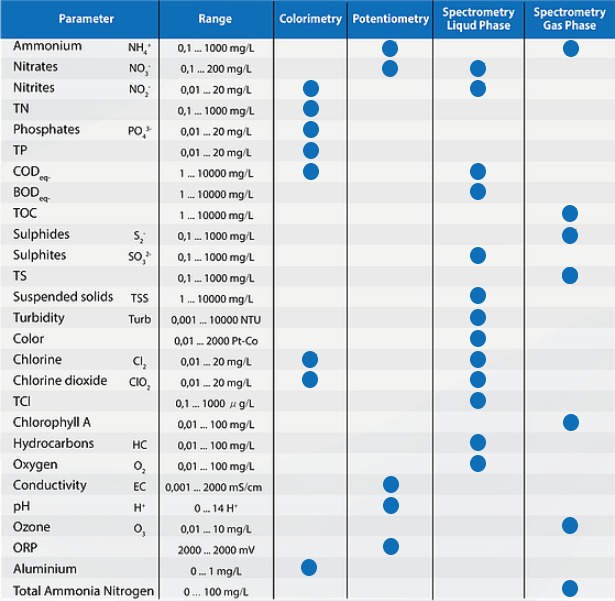

Effluent Monitoring System

EQMS (Effluent Quality Monitoring System) technology is based on unique method FTLS UV spectroscopy which associates proprietary high resolution spectrograph with Fourier Transform & Least Square mathematical treatment. So, you can believe in our knowledgeable and responsive support team to address your unique needs for the water or air applications throughout your entire process.

Our goal for the future is to continue to provide customers with reliable instruments, proven methods, easy procedures, and outstanding technical support. We will strive to be best choice brand offering trust and assurance to our customers.

Applications

- Waste water treatment plant – pH, COD, BOD, TSS, NO3-, NO2-, PO43-, Color.

- Surface Treatment– River Lake, rainfall water, Hydrocarbons, Salinity, COD, pH, NH4+

- Sea Water– Desalination plant, Harbour S2, Hydrocarbon, NH4+, NO2

- Drinking Water– Portablization plant, pH, Chlorine, turbidity, Color.

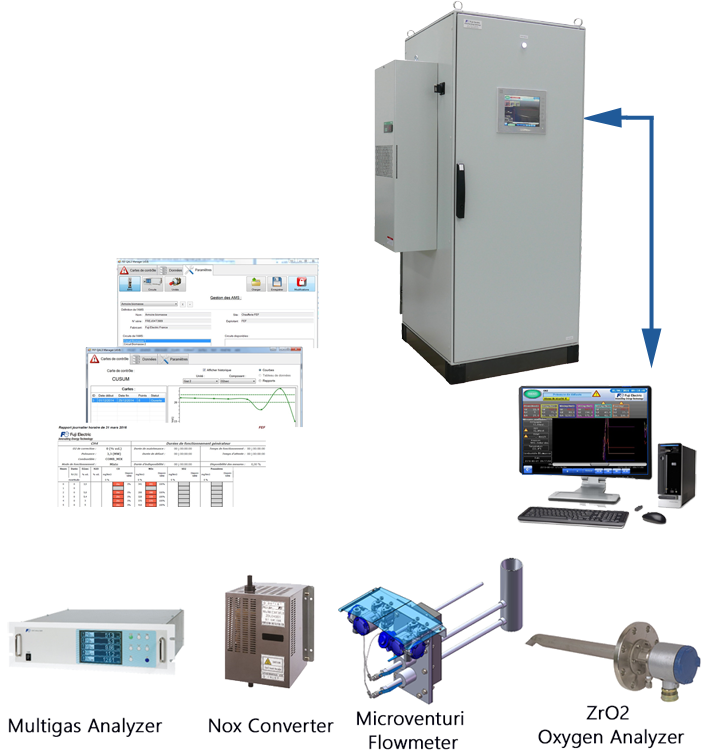

Emission/Stack Monitoring System

Stack Monitoring is the process of monitoring the emissions coming out of the stacks to keep a check on the pollutants thrown out in the air.

The major pollutants that stacks emit are Carbon Monoxide (CO), Methane Gas(CH4), oxides of Sulphur, and Nitrogen i.e. SOx and NOx, and hydrocarbon compounds.

Our CEMS are used for the measurement of a number of pollutants from within the stack environment. Monitoring within the stack presents a number of problems due to extremes of temperature, velocity of sample and pressure.

Now, there are essentially two types of stack monitoring systems.

- In-Situ Measurement Method

- Extractive Dilution Method

In in-situ measurement system, the emission sensors are placed directly at or inside the stack for emission parameters monitoring. Whereas, in extractive dilution method, a sample of emission is taken and sent to the analyzers placed away from the emission stack.

Stack Monitoring Parameters and Standards / Limits as per CPCB for Boiler & DG Sets Emission

Sr no | Stack Monitoring Parameters for Boilers and DG Sets |

1 | Particulate Matter (PM) |

2 | Sulphur Dioxide (SO2) |

3 | Oxides of Nitrogen (NOx) |

4 | Total Fluoride (F) |

5 | Mercury (Hg) |

6 | Chlorine (Cl) |

7 | Hydrochloric Acid Vapor & Mist (HCl) |

8 | Sulphuric Acid Mist (H2SO4) |

9 | Carbon Monoxide (CO) |

10 | Lead (Pb) |

Ambient Air Monitoring System

An Air Quality Monitoring Station (AQMS) is a system that measures metrological parameters such as wind speed, wind direction, rainfall, radiation, temperature, barometric pressure and ambient parameters. The AQMS also integrates a series of ambient analyzers to monitor the concentration of air pollutants (such as SO2, NOx, CO, O3, THC, PM, etc.), continuously.

PIEZOMETER

Piezometer

Our PIEZ0METER (Digital Water Level Recorder) provides highly accurate water level measurement for a wide variety of applications, including those in harsh environments. The submersible pressure transducers have a dynamicpressure compensation system, enabling high accuracy measurements over a wide measuring range. The water level sensor is adapted to all data loggers, telemetry, monitoring equipment, and LCD/LED displays.

Each of the stainless steel water level sensors consist of a solid state submersible pressure transducer encapsulated in a stainless steel 2-10 inch length housing. The water level sensor has a molded-on waterproof cable and a two-wire 4-20 mA high level output for connection to a monitoring device. A 10 mtrs cable is standard, and optional cable lengths are available up to 500 meters can be attached with the existing sensor 4-20m. A signal based sensors are immune to signal losses in long distance transmissions

TECHNICAL SPECIFICATIONS | |

Output signals | 4-20mA, 0-10mA, 0-5V, 1-5V |

Measured range | 0-0.5 200mH2O |

Max overload | 150% of sensor range |

Applicable media | Liquid, Water |

Accuracy | +0.2% FS/year, +D.5% FS/year |

Stability | z0.25% FS/year |

Housing material | Stainless steel |

Cable material | Polyvinyl Fluoride, PTFE |

Power supply | 12Vdc |

Ambient temperature | -2D-85°C |

Process temperature | -20-85°C |

Compensation temperature | -20 85°C |

Protection class | IP68 water proof |